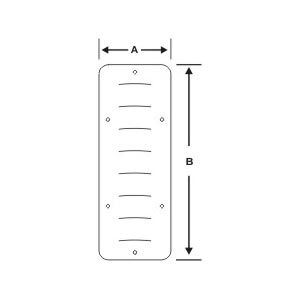

ITEM: Metal Louvre

| PART NO. | A | B |

|---|---|---|

| ML2 | 90 | 210 |

| ML3 | 90 | 245 |

Material: Mild Steel

Finish: Powder Coated

Color: RAL 7032 / RAL 7035

All dimensions are in mm

| PART NO. | A | B |

|---|---|---|

| ML2 | 90 | 210 |

| ML3 | 90 | 245 |

Material: Mild Steel

Finish: Powder Coated

Color: RAL 7032 / RAL 7035

All dimensions are in mm

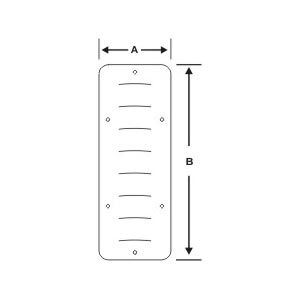

| LENGTH | WIDTH | THICK |

|---|---|---|

| (MTRS.) | (MTRS.) | (MM) |

| 1.22 | 1.22 | 1 TO 40 |

| 1.22 | 1.83 | 1 TO 40 |

| 1.22 | 2.44 | 1 TO 40 |

Material : Paper Based Industrial Laminate

Color : Brown / Brown. Brown / Grey, Grey / Grey

Finish : Matt/ Gloss I Grade : Electrical Pl /P2/P3

| Part No. | Width (mm) | Suitable Bus Ba Size |

|---|---|---|

| HSS17 | 17 | 9x3mm, 10x3mm |

| HSS20 | 20 | 9x6mm, 10x6mm, 12x3mm |

| HSS25 | 25 | 12x6mm, 15x3mm |

| HSS30 | 30 | 19x6mm |

| HSS35 | 35 | 20x6mm, 25x3mm |

| HSS41 | 41 | 25x6mm, 25x10mm, 25x20mm |

| HSS48 | 48 | 25x12mm, 30x6mm, 30x10mm |

| HSS55 | 55 | 30x12mm, 38x6mm |

| HSS61 | 61 | 38x9mm, 38x12mm, 40x6mm, 40x10mm |

| HSS73 | 73 | 50x6mm |

| HSS81 | 81 | 50x10mm, 50x12mm |

| HSS85 | 85 | 60x6mm, 60x10mm |

| HSS93 | 93 | 60x12mm, 75x6mm |

| HSS103 | 103 | 75x10mm, 75x12mm |

| HSS110 | 110 | 90x6mm, 90x12mm |

| HSS128 | 128 | 100x6mm, 100x10mm |

| HSS140 | 140 | 100x12mm |

| HSS170 | 170 | 125x6mm, 125x12mm, 150x6mm |

| HSS190 | 190 | 150x6mm, 150x10mm, 150x12mm |

| HSS210 | 210 | 175x6mm, 175x10mm, 175x12mm |

| HSS230 | 230 | 200x12mm |

| Properties | Values |

|---|---|

| Working Tempreture | 90°C |

| Dielectric Strength | 10 KV/mm |

| Insulation Resistance | 20 X 10 10 Ohms at 500V. DC |

| Tensile Strength | 400 Kg/cm (min) |

| Ultimate Elongation | 100% (min) |

| Chemical Resistance | Good |

| Chemical Resistance | Good |

| Fire Resistance | Self Extinguishing |

| Shrinkable Tempreture | 105°C – 110°C for 4-5 mts. |

| Shrinkage | 30% – 35% |

| Dimensional Variance | +- 1.5mm (for Size 17mm to 61 mm) |

| +- 3.0mm (for size 73mm to 230mm) |

Color: Red / Yellow / Blue / Black / Green

Length/Roll: 100 Meters / 50 Meters

Wall Thickness : 100 Microns / 180 Microns

Material : PVC

HSS : Heat Shrink Sleeves

Please mention Color, Wall Thickness & Length per roll

required beside the product part no. in the purchase order.

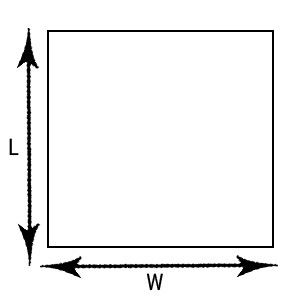

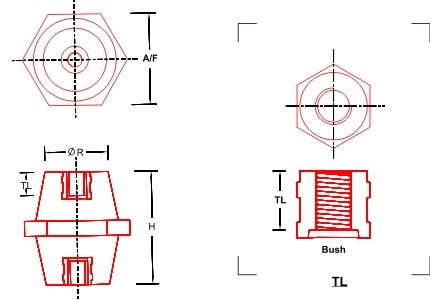

| Height | Part No. | Insert (M) | Rt | Rb | TL | Nominal Voltage |

|---|---|---|---|---|---|---|

| H (mm) | (mm) | (mm) | (mm) | AC/DC | ||

| 25 | C 625 | M6 | 19 | 25 | 7 | 400/500 |

| 30 | C 630 | M6 | 25 | 30 | 7 | 600/750 |

| 30 | C 830 | M8 | 25 | 30 | 9 | 600/750 |

| 35 | C 635 | M6 | 28 | 35 | 7 | 600/750 |

| 35 | C 835 | M8 | 28 | 35 | 12 | 600/750 |

| 40 | C 640 | M6 | 33 | 40 | 9 | 600/750 |

| 40 | C 840 | M8 | 33 | 40 | 12 | 1000/1200 |

| 40 | C 1040 | M10 | 33 | 40 | 12 | 1000/1200 |

| 45 | C 845 | M8 | 33 | 40 | 12 | 1000/1200 |

| 45 | C 1045 | M10 | 33 | 40 | 12 | 1000/1200 |

| 50 | C 850 | M8 | 40 | 50 | 12 | 1200/1500 |

| 50 | C 1050 | M10 | 40 | 50 | 15 | 1200/1500 |

| 50 | C 1250 | M12 | 40 | 50 | 17 | 1200/1500 |

| 60 | C 1060 | M10 | 40 | 50 | 15 | 1500/1800 |

| 60 | C 1260 | M12 | 40 | 50 | 17 | 1500/1800 |

| 60 | C 1060 | M10 | 40 | 60 | 15 | 1500/1800 |

| 60 | C 1260 | M12 | 40 | 60 | 17 | 1500/1800 |

| 70 | C 1070 | M10 | 40 | 50 | 15 | 2000/2400 |

| 70 | C 1270 | M12 | 40 | 50 | 17 | 2000/2400 |

| 75 | C 1075 | M10 | 40 | 50 | 15 | 2000/2400 |

| 75 | C 1275 | M12 | 40 | 50 | 17 | 2000/2400 |

| 80 | C 1080 | M10 | 40 | 50 | 15 | 2000/2400 |

| 80 | C 1280 | M12 | 40 | 50 | 17 | 2000/2400 |

Material : DMC (Dough Molding Compound)

All Dimensions are in MM

TL : Effective Thread Length

Insert : Brass / Steel (Zinc Plated)

Color : Red / Brown / Grey

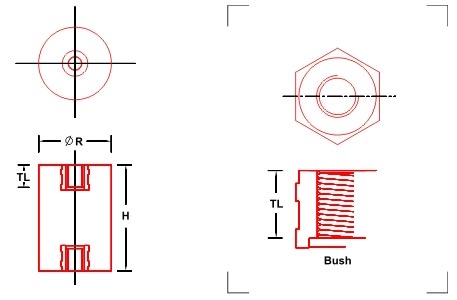

| Height | Part No. | Insert (M) | A/F | R | TL | Nominal Voltage |

|---|---|---|---|---|---|---|

| H (mm) | (mm) | (mm) | (mm) | AC/DC | ||

| 25 | H 625 | M6 | 21 | 16 | 7 | 400/500 |

| 25 | H 825 | M8 | 21 | 16 | 9 | 400/500 |

| 30 | H 630 | M6 | 31 | 25 | 7 | 600/750 |

| 30 | H 830 | M8 | 31 | 25 | 9 | 600/750 |

| 35 | H 635 | M6 | 32 | 26 | 7 | 600/750 |

| 35 | H 835 | M8 | 32 | 26 | 12 | 600/750 |

| 35 | H 1035 | M10 | 32 | 26 | 12 | 600/750 |

| 40 | H 640 | M6 | 39 | 31 | 9 | 600/750 |

| 40 | H 840 | M8 | 39 | 31 | 12 | 1000/1200 |

| 40 | H 1040 | M10 | 39 | 31 | 12 | 1000/1200 |

| 45 | H 845 | M8 | 41 | 32 | 12 | 1000/1200 |

| 45 | H 1045 | M10 | 41 | 32 | 12 | 1000/1200 |

| 50 | H 850 | M8 | 48 | 36 | 12 | 1200/1500 |

| 50 | H 1050 | M10 | 48 | 36 | 15 | 1200/1500 |

| 50 | H 1250 | M12 | 48 | 36 | 17 | 1200/1500 |

| 60 | H 1060 | M10 | 52 | 38 | 15 | 1500/1800 |

| 60 | H 1260 | M12 | 52 | 38 | 17 | 1500/1800 |

| 65 | H 1065 | M10 | 55 | 41 | 15 | 1500/1800 |

| 65 | H 1265 | M12 | 55 | 41 | 17 | 1500/1800 |

| 70 | H 1070 | M10 | 55 | 41 | 15 | 2000/2400 |

| 70 | H 1270 | M12 | 55 | 41 | 17 | 2000/2400 |

| 75 | H 1075 | M10 | 55 | 41 | 15 | 2000/2400 |

| 75 | H 1275 | M12 | 55 | 41 | 17 | 2000/2400 |

Material: DMC (Dough Molding Compound)

All Dimensions are in MM

TL: Effective Thread Length

Insert: Brass / Steel (Zinc Plated)

Color: Red

| Height | Part No. | Insert (M) | R | TL | Nominal Voltage |

|---|---|---|---|---|---|

| H (mm) | (mm) | (mm) | AC/DC | ||

| 25 | CY 625 | M6 | 25 | 7 | 400/500 |

| 30 | CY 630 | M6 | 30 | 9 | 600/750 |

| 30 | CY 830 | M8 | 30 | 9 | 600/750 |

| 40 | CY 64030 | M6 | 30 | 12 | 1000/1200 |

| 40 | CY 84030 | M8 | 30 | 12 | 1000/1200 |

| 40 | CY 640 | M6 | 40 | 12 | 1000/1200 |

| 40 | CY 840 | M8 | 40 | 12 | 1000/1200 |

| 40 | CY 1040 | M10 | 40 | 12 | 1000/1200 |

| 50 | CY 85040 | M8 | 40 | 17 | 1200/1500 |

| 50 | CY105040 | M10 | 40 | 17 | 1200/1500 |

| 50 | CY 850 | M8 | 50 | 17 | 1200/1500 |

| 50 | CY 1050 | M10 | 50 | 17 | 1200/1500 |

| 50 | CY 1250 | M12 | 50 | 17 | 1200/1500 |

| 60 | CY 106050 | M10 | 50 | 17 | 1500/1800 |

| 60 | CY 126050 | M12 | 50 | 17 | 1500/1800 |

| 60 | CY 1060 | M10 | 60 | 17 | 1500/1800 |

| 60 | CY 1260 | M12 | 60 | 17 | 1500/1800 |

Material : DMC (Dough Molding Compound)

All Dimensions are in MM

TL : Effective Thread Length

Insert : Brass / Steel (Zinc Plated)

Color : Red / Brown / Grey

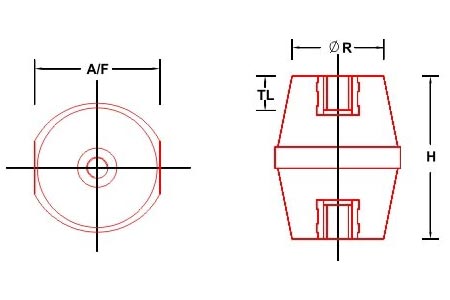

| Height | Part No. | Insert (M) | A/F | R | TL | Nominal Voltage |

|---|---|---|---|---|---|---|

| H (mm) | (mm) | (mm) | (mm) | AC/DC | ||

| 25 | D 625 | M6 | 21 | 16 | 7 | 400/500 |

| 25 | D 825 | M8 | 21 | 16 | 9 | 400/500 |

| 30 | D 630 | M6 | 31 | 25 | 7 | 600/750 |

| 30 | D 830 | M8 | 31 | 25 | 9 | 600/750 |

| 35 | D 635 | M6 | 32 | 26 | 7 | 600/750 |

| 35 | D 835 | M8 | 32 | 26 | 12 | 600/750 |

| 35 | D 1035 | M10 | 32 | 26 | 12 | 600/750 |

| 40 | D 640 | M6 | 39 | 31 | 9 | 600/750 |

| 40 | D 840 | M8 | 39 | 31 | 12 | 1000/1200 |

| 40 | D 1040 | M10 | 39 | 31 | 12 | 1000/1200 |

| 45 | D 845 | M8 | 41 | 32 | 12 | 1000/1200 |

| 45 | D 1045 | M10 | 41 | 32 | 12 | 1000/1200 |

| 50 | D 850 | M8 | 48 | 36 | 12 | 1200/1500 |

| 50 | D 1050 | M10 | 48 | 36 | 15 | 1200/1500 |

| 50 | D 1250 | M12 | 48 | 36 | 17 | 1200/1500 |

| 60 | D 1060 | M10 | 52 | 38 | 15 | 1500/1800 |

| 60 | D 1260 | M12 | 52 | 38 | 17 | 1500/1800 |

| 65 | D 1065 | M10 | 55 | 41 | 15 | 1500/1800 |

| 65 | D 1265 | M12 | 55 | 41 | 17 | 1500/1800 |

| 70 | D 1070 | M10 | 55 | 41 | 15 | 2000/2400 |

| 70 | D 1270 | M12 | 55 | 41 | 17 | 2000/2400 |

| 75 | D 1075 | M10 | 55 | 41 | 15 | 2000/2400 |

| 75 | D 1275 | M12 | 55 | 41 | 17 | 2000/2400 |

Material : DMC (Dough Molding Compound)

All Dimensions are in MM

TL : Effective Thread Length

Insert : Brass / Steel (Zinc Plated)

Color : Red / Brown / Grey

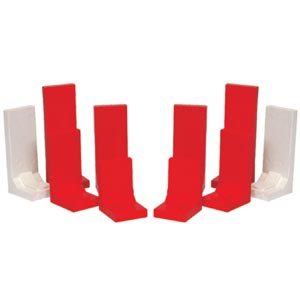

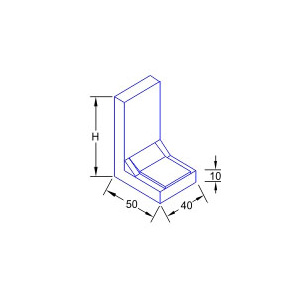

| Part No. | Height |

|---|---|

| L 60 | 60 |

| L 85 | 85 |

| L 105 | 105 |

| L 125 | 125 |

| L 150 | 150 |

Material: SMC (Sheet Molding Compound) / DMC (Dough Molding Compound)

All Dimensions are in MM

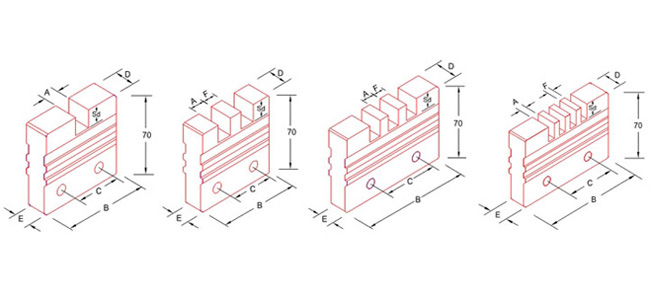

| Bus Bar Slot | Part No. | A | B | C | D | E | F | Sd |

|---|---|---|---|---|---|---|---|---|

| 6mm x 1 | 106S | 7 | 50 | 22 | 14 | 10 | – | 15 |

| 10mm x 1 | 110S | 11 | 50 | 22 | 14 | 10 | – | 15 |

| 12mm x 1 | 112S | 14 | 50 | 22 | 14 | 10 | – | 15 |

| 6mm x 1 | 106W | 7 | 60 | 32 | 14 | 10 | – | 15 |

| 10mm x 1 | 110W | 11 | 60 | 32 | 14 | 10 | – | 15 |

| 12mm x 1 | 112W | 14 | 60 | 32 | 14 | 10 | – | 15 |

| 6mm x 1 | 106K | 7 | 70 | 40 | 20 | 16 | – | 15 |

| 10mm x 1 | 110K | 11 | 70 | 40 | 20 | 16 | – | 15 |

| 12mm x 1 | 112K | 14 | 70 | 40 | 20 | 16 | – | 15 |

| 6mm x 2 | 206W | 7 | 60 | 32 | 14 | 10 | 6 | 15 |

| 10mm x 2 | 210W | 11 | 60 | 32 | 14 | 10 | 9 | 15 |

| 12mm x 2 | 212W | 14 | 70 | 32 | 14 | 10 | 11 | 15 |

| 6mm x 2 | 206K | 7 | 70 | 40 | 20 | 16 | 6 | 15 |

| 10mm x 2 | 210K | 11 | 70 | 40 | 20 | 16 | 9 | 15 |

| 12mm x 2 | 212K | 14 | 70 | 40 | 20 | 16 | 11 | 15 |

| 6mm x 3 | 306W | 7 | 70 | 32 | 14 | 10 | 6 | 15 |

| 10mm x 3 | 310W | 11 | 80 | 50 | 14 | 10 | 9 | 15 |

| 12mm x 3 | 312W | 14 | 90 | 50 | 15 | 11 | 11 | 15 |

| 6mm x 3 | 306K | 7 | 70 | 40 | 20 | 16 | 6 | 15 |

| 10mm x 3 | 310K | 11 | 100 | 50 | 20 | 16 | 6 | 15 |

| 12mm x 3 | 312K | 14 | 100 | 50 | 20 | 16 | 11 | 15 |

| 6mm x 4 | 406W | 7 | 80 | 50 | 14 | 10 | – | 15 |

| 6mm x 4 | 406K | 7 | 100 | 50 | 20 | 16 | – | 15 |

| 10mm x 4 | 410K | 11 | 130 | 80 | 20 | 16 | 9 | 15 |

| 12mm x 4 | 412K | 14 | 130 | 80 | 20 | 16 | 11 | 15 |

Material: SMC (Sheet Molding Compound) / DMC (Dough Molding Compound)

All Dimensions are in MM

Sd: Depth of the Slot

Mounting Hole: ᴓ 8.5mm

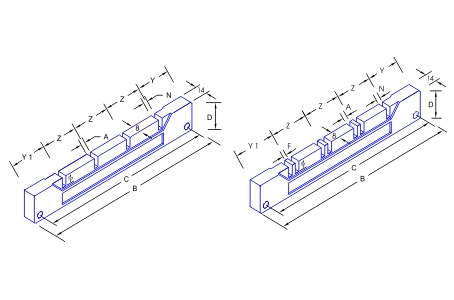

| Bus Bar Slot | Part No. | A | B | C | D | N | Z | Y | Y1 | F | Sd |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 6mm x 1 x TP&N | TPN 107/30 | 7 | 300 | 280 | 50 | 7 | 65 | 52.5 | 52.5 | – | 15 |

| 10mm x 1 x TP&N | TPN 111/30 | 11 | 300 | 280 | 50 | 7 | 65 | 52.5 | 52.5 | – | 15 |

| 12MM x 1 x TP&N | TPN 114/30 | 14 | 300 | 280 | 50 | 7 | 65 | 52.5 | 52.5 | – | 15 |

| 6mm x 1 x TP&N | TPN 107/35 | 7 | 350 | 328 | 50 | 7 | 75 | 62.5 | 62.5 | – | 15 |

| 10mm x 1 x TP&N | TPN 111/35 | 11 | 350 | 328 | 50 | 7 | 75 | 62.5 | 62.5 | – | 15 |

| 12MM x 1 x TP&N | TPN 114/35 | 14 | 350 | 328 | 50 | 7 | 75 | 62.5 | 62.5 | – | 15 |

| 6mm x 1 x TP&N | TPN 107/42 | 7 | 420 | 396 | 60 | 7 | 100 | 52.5 | 68 | – | 15 |

| 10mm x 1 x TP&N | TPN 111/42 | 11 | 420 | 396 | 60 | 7 | 100 | 52.5 | 68 | – | 15 |

| 12MM x 1 x TP&N | TPN 114/42 | 14 | 420 | 396 | 60 | 7 | 100 | 52.5 | 68 | – | 15 |

| 6mm x 2 x TP&N | TPN 207/35 | 7 | 350 | 328 | 50 | 7 | 70 | 78 | 62.5 | 6 | 15 |

| 10mm x 2 x TP&N | TPN 211/35 | 11 | 350 | 328 | 50 | 11 | 70 | 78 | 62.5 | 9 | 15 |

| 12mm x 2 x TP&N | TPN 214/35 | 14 | 350 | 328 | 50 | 14 | 70 | 78 | 62.5 | 11 | 15 |

| 6mm x 2 x TP&N | TPN 207/42 | 7 | 420 | 396 | 60 | 7 | 100 | 52.5 | 69 | 6 | 15 |

| 10mm x 2 x TP&N | TPN 211/42 | 11 | 420 | 396 | 60 | 11 | 100 | 52.5 | 69 | 9 | 15 |

| 12mm x 2 x TP&N | TPN 214/42 | 14 | 420 | 396 | 60 | 14 | 100 | 52.5 | 69 | 11 | 15 |

Material: SMC (Sheet Molding Compound) / DMC (Dough Molding Compound)

All Dimensions are in MM

TPN: Triple Pole & Neutral

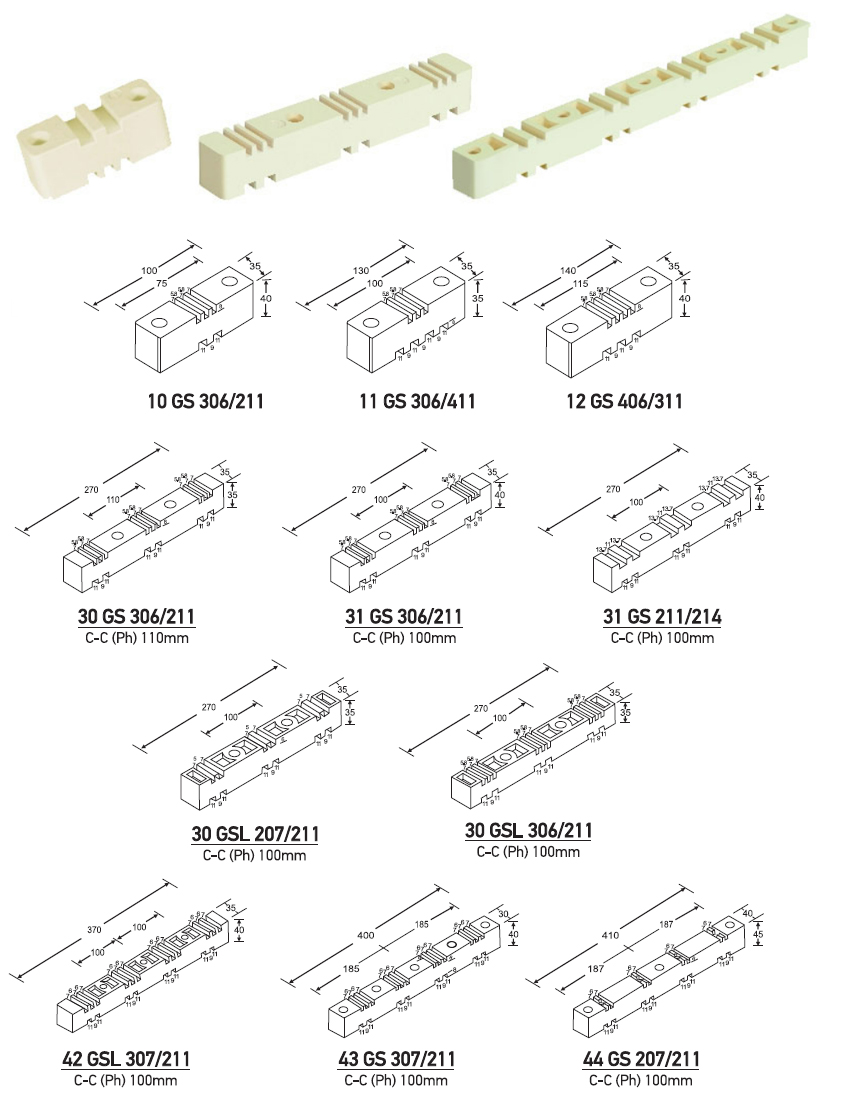

| Part No. |

|---|

| 10 GS 306/211 |

| 11 GS 306/411 |

| 12 GS 406/311 |

| 30 GS 306/211 |

| 31 GS 306/211 |

| 31 GS 211/214 |

| 30 GSL 207/211 |

| 30 GSL 306/211 |

| 42 GSL 307/211 |

| 43 GS 307/211 |

| 44 GS 207/211 |

Material: SMC (Sheet Molding Compound) / DMC (Dough Molding Compound)

All Dimensions are in MM

Mounting Hole Suitable for M8 Stud

C-C (ph): Centre to Centre Between Phases

GS: Grip Support

| Part No. | Height (mm) | Width (mm) | Thickness (mm) |

|---|---|---|---|

| FRLA353505 | 35 | 35 | 5 |

| FRLA505006 | 50 | 50 | 6 |

Color : White

Length: 2 Meters

| Part No. | Width (mm) | Thickness (mm) |

|---|---|---|

| FRFP2510 | 25 | 10 |

| FRFP3010 | 30 | 10 |

| FRFP4010 | 40 | 10 |

| FRFP5010 | 50 | 10 |

| FRFP6010 | 60 | 10 |

| FRFP7010 | 70 | 10 |

| FRFP2520 | 25 | 20 |

| FRFP3020 | 30 | 20 |

| FRFP4020 | 40 | 20 |

| FRFP5020 | 50 | 20 |

| FRFP6020 | 60 | 20 |

| FRFP7020 | 70 | 20 |

Color : White

Length: 1 Meter

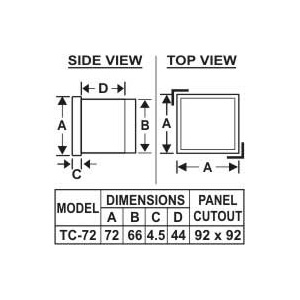

| Properties | Values |

|---|---|

| Description | Moving Iron Meter of 90° deflection with Interchangable Scale facility |

| Movement Type | Moving Iron Spring Mounted Jewel bearing Suspension |

| Accuracy | ± 1.5% of Full Scale As Per IS 1248 |

| Range | Current (A.): 0-1A. To 1-100A. (Direct) Through CT /1A. Or /5A. For Higher Currents. |

| Range | Voltage (V.): 0-50V. To 0-600V. (Direct) Through PT for Higher Voltages. |

| Self Consumption | Ammeter (upto 5A. AC) – < 0.6VA Voltmeter (upto 500V. AC) – < 5VA |

| Operating Voltage | 600V. RMS Max. |

| Test Voltage | 2.5 time for 1 min. at 50 Hz |

| Construction and Design | As per IS 1248 |

| Scale | According to DIN 43802 |

| Case / Housing Material | Black Nylon, Dimensions as per DIN 43700 |

| Bezel | Black Poly Carbonate and Nylon glass filled Dimensions as per DIN 43718 |

| Glass Face Plate | Poly Carbonate (Shatter Proof) |

| Tempreture Conditions | 10°C to 55°C, RH < 90% |

| Front Protection | IP52 Protection as Per IS2147 |

| Terminal Protection | IP20 Terminal Protection |

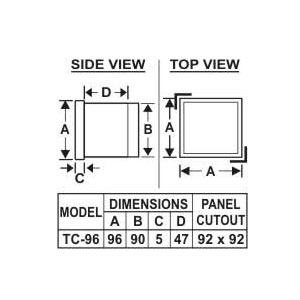

| Properties | Values |

|---|---|

| Description | Moving Iron Meter of 90° deflection with Interchangable Scale facility |

| Movement Type | Moving Iron Spring Mounted Jewel bearing Suspension |

| Accuracy | ± 1.5% of Full Scale As Per IS 1248 |

| Range | Current (A.): 0-1A. To 1-100A. (Direct) Through CT /1A. Or /5A. For Higher Currents. |

| Range | Voltage (V.): 0-50V. To 0-600V. (Direct) Through PT for Higher Voltages. |

| Self Consumption | Ammeter (upto 5A. AC) – < 0.6VA Voltmeter (upto 500V. AC) – < 5VA |

| Operating Voltage | 600V. RMS Max. |

| Test Voltage | 2.5 time for 1 min. at 50 Hz |

| Construction and Design | As per IS 1248 |

| Scale | According to DIN 43802 |

| Case / Housing Material | Black Nylon, Dimensions as per DIN 43700 |

| Bezel | Black Poly Carbonate and Nylon glass filled Dimensions as per DIN 43718 |

| Glass Face Plate | Poly Carbonate (Shatter Proof) |

| Tempreture Conditions | 10°C to 55°C, RH < 90% |

| Front Protection | IP52 Protection as Per IS2147 |

| Terminal Protection | IP20 Terminal Protection |

| Part No. | Size |

|---|---|

| ECL251P | 1 Pin |

| ECL252P | 2 Pin |

Material : Brass

Plating : Bright Nickle

| Part No. | Size | Length | Width | Height | No. of Holes |

|---|---|---|---|---|---|

| NLDM7W | 7 Way | 60 | 6.5 | 9 | 7+1 |

| NLDM10W | 10 Way | 80 | 6.5 | 9 | 10+1 |

| NLDM13W | 13 Way | 100 | 6.5 | 9 | 13+1 |

| EB1M | 1 Mtr. | 1000 | 7 | 9 | 144 |

| EB2M | 1 Mtr. | 1000 | 8 | 12 | 144 |

Material: Brass

Termination: M5/M6

Plating: Bright Nickle

All Dimensions are in mm

NLDM: Neutral Link Din Mounting

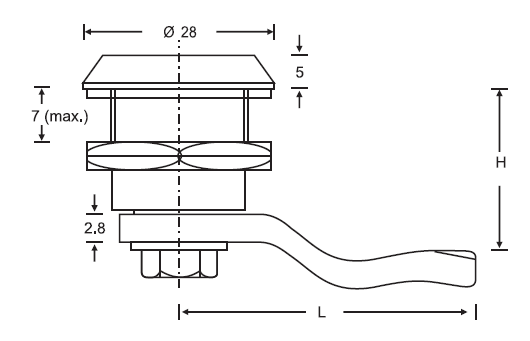

| Part No. | H | L |

|---|---|---|

| PL12535 | 25 | 35 |

| Part No. | H | L |

|---|---|---|

| PL22535 | 25 | 35 |

| Part No. | H | L |

|---|---|---|

| PL32535 | 25 | 35 |

| Part No. | H | L |

|---|---|---|

| PL42535 | 25 | 35 |

Body Material : Zinc Alloy

Lever Material : Mild Steel

All Dimensions are in MM

Plating : Chrome

| Part No. | Width W | Thickness T |

|---|---|---|

| FTG123 | 12 | 3 |

| FTG153 | 15 | 3 |

| FTG203 | 20 | 3 |

| FTG253 | 25 | 3 |

| FTG403 | 40 | 3 |

| FTG205 | 20 | 5 |

| FTG255 | 25 | 5 |

| FTG405 | 40 | 5 |

| FTG505 | 50 | 5 |

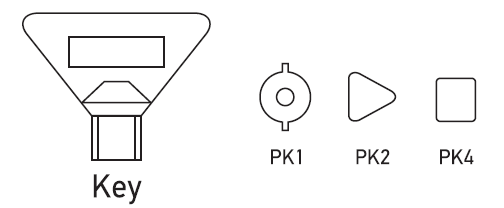

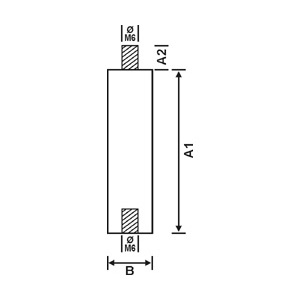

| Part No. | A1 | A2 | THREAD | HEX PROFILE(B) |

|---|---|---|---|---|

| MSPMF106 | 10 | 8 | M6 | 10 |

| MSPMF156 | 15 | 8 | M6 | 10 |

| MSPMF206 | 20 | 8 | M6 | 10 |

| MSPMF256 | 25 | 8 | M6 | 10 |

| MSPMF306 | 30 | 8 | M6 | 10 |

| MSPMF406 | 40 | 10 | M6 | 10 |

| MSPMF506 | 50 | 10 | M6 | 10 |

| MSPMF606 | 60 | 10 | M6 | 10 |

| MSPMF706 | 70 | 10 | M6 | 10 |

| MSPMF806 | 80 | 10 | M6 | 10 |

| MSPMF906 | 90 | 10 | M6 | 10 |

| MSPMF1006 | 100 | 10 | M6 | 10 |

| MSPMF108 | 10 | 8 | M8 | 11 |

| MSPMF158 | 15 | 8 | M8 | 11 |

| MSPMF208 | 20 | 8 | M8 | 11 |

| MSPMF258 | 25 | 8 | M8 | 11 |

| MSPMF308 | 30 | 8 | M8 | 11 |

| MSPMF408 | 40 | 8 | M8 | 11 |

| MSPMF508 | 50 | 8 | M8 | 11 |

| MSPMF608 | 60 | 8 | M8 | 11 |

| MSPMF708 | 70 | 8 | M8 | 11 |

| MSPMF808 | 80 | 8 | M8 | 11 |

| MSPMF908 | 90 | 8 | M8 | 11 |

| MSPMF1008 | 100 | 8 | M8 | 11 |

Material: Mild Steel

Plating: Zinc Passivated

All Dimensions are in mm

MSPMF: Mild Steel Pillar Male/Female

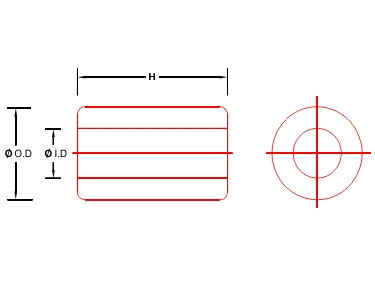

| Part No. | OD | ID | Height(H) |

|---|---|---|---|

| CUS1215A | 12 | 6.5 | 15 |

| CUS1220A | 12 | 6.5 | 20 |

| CUS1315A | 13 | 6.5 | 15 |

| CUS1320A | 13 | 6.5 | 20 |

Material: Electrolytic Grade Copper

Plating: Tin

CUS: Copper Spacer

All dimesions are in mm